Tempering

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point

for a certain period of time, then allowing it to cool in still air.

The exact temperature determines the amount of hardness removed, and

depends on both the specific composition of the alloy and on the desired

properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered to much higher temperatures.

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point

for a certain period of time, then allowing it to cool in still air.

The exact temperature determines the amount of hardness removed, and

depends on both the specific composition of the alloy and on the desired

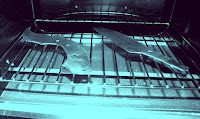

properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered to much higher temperatures.I took two of my knife blanks today and tempered them in my toaster-oven. I assumed the broil

option would put the temperature at around 450 degrees but when I took them out after an hour and a half, they were purplish-blue color telling me according to the above diagram that the oven was actually getting over 550 degrees!

Well, tomorrow I will finish off the sanding using grits from 350 to 1500. I did some sanding today from 60 to 120, but tomorrow is when I get out all the fine scratches.

Then it's on to the handles!

Comments

Post a Comment